Over three decades ago, when computer aided design (CAD) first entered the scene, how many of its early adopters could have imagined how the technology would transform the world of design?

What began as a digital design tool is now much more. CAD technology was soon joined by computer aided manufacturing enabling digital design files to be converted to digital fabrication instructions that could be delivered directly to the machines used to execute the designs.

The past decade’s advances in computing power, digital design and fabrication software and hardware have exponentially expanded the versatility and functionality of these tools. Yesterday’s architects could use CAD systems to create rough outlines or crude visual renderings of their planned projects. Today’s architects can develop full digital models and visualizations that enable them to examine every detail at near photo-realistic levels, and even perform virtual walk-throughs.

Design visualization isn’t the only advance in digital fabrication that is transforming the world of architecture. Every day, a generation of designers, architects and computer scientists are working together to find new ways to combine art and science to build a fresh, innovative sustainable future. In this article, find out how today’s architects are using digital fabrication to transform their practices.

What is digital fabrication?

Digital fabrication is a manufacturing method that combines machine manufacturing tools and processes with computer guidance systems. In digital fabrication, a digital set of instructions is built based on a design file. Then, these instructions are transferred to various machines that can execute the instructions precisely and repeatedly.

Because the designs and instructions are digitized, they can be altered, adjusted or scaled quickly. This shortens the concept to construction timeline and allows designers and architects to create and test custom designs in a virtual setting before investing in physical prototyping or construction. Using the power of computers, architects can explore new avenues of design incorporating organic shapes that would have been technically impossible or cost-prohibitive in the past.

What digital fabrication tools and machines do architects use to create their innovative designs?

Digital fabrication employs both software and hardware to achieve amazing architectural outcomes. The process begins with design tools that enable architects to encode their ideas in digital formats, then alter and assess the design’s performance in a virtual setting.

Examples of software used to support digital fabrication in architecture and other disciplines include:

- AutoCAD

- Revit

- 3D Max

- Autodesk Fusion 360

- SOLIDWORKS 3D CAD and CAM

- Inventor HSM and HSM CAM

These and other computer aided design and manufacturing applications integrate with different fabrication and construction tools to build 3D objects through either additive or subtractive processes.

Some computer-guided manufacturing devices architects use include:

3D printers - Industrial 3D printers can be used to create small-scale models, large projects or to fabricate individual components of a project. The largest-scale 3D printers can print walls and foundations, constructing complete buildings with precision and speed. (Some 3D machines can build a house in as little as two days.)

CNC machines - Computer numerical control (CNC) describes the encoding used to control a variety of machines used for architectural prototyping or construction. Within the CNC family of tools are drilling machines, milling machines, routers, plasma, laser or water jet cutting machines, lathe machines, electrical discharge machines and grinders.

Multi-axis robots - Multi-axis robots can perform a number of tasks, depending on their design. In the field of architecture, the latest generation of multi-axis robots are being used to automate the production of wall and roofing frames and lay bricks.

Bending, forming and shaping machines - Machines that can round edges, shape metal pieces and perform other robotic manipulations enable these complex tasks to be performed quickly and precisely.

How are digital fabrication technologies transforming architecture?

Digital fabrication enables architects to visualize their designs and explore concepts from multiple points of view in a virtual environment. Freed from the task of building physical models and prototypes, architects can test alternate designs, evaluate costs and significantly speed the process of conceptualization and planning.

With the ability to rapidly change the design specifications for a piece, digital fabricators can produce complex or organically-shaped objects without any loss of efficiency.

Designers can enter the parameters of a particular material and construction project and produce new designs that meet all the necessary safety and structural requirements of the build while using the least amount of materials.

This technological advance had led to an explosion of innovation in the use of unique, intricate features formed from concrete, wood and other materials by designers and architects.

Machine assisted on-site and off-site manufacturing speeds the pace of construction and ensures uniformity between building components. One design can be replicated with exact precision by a single machine, or production can be accelerated by distributing the code to multiple machines.

What are some examples of structures, furnishings or building components that were constructed using digital fabrication?

New applications of digital fabrications continue to appear as architects and design teams embrace the expansive power of this technology. For instance, the images in this April 2022 article published in the 3D Printing and Additive Manufacturing Journal illustrate the stunning effects architects can achieve using 3D printed formwork and concrete.

In September 2022, The Cornell Chronicle noted the construction of a first-of-its-kind 3D printed home built using both concrete and wood.

The stunning pavilion located in the University of Michigan’s Matthaei Botanical Gardens is a robotically fabricated structure (RFS) made from off-the-shelf lumber. The design was perfected using precise algorithms and assembled by robots in the Taubman College digital fabrication lab in a process that minimizes waste.

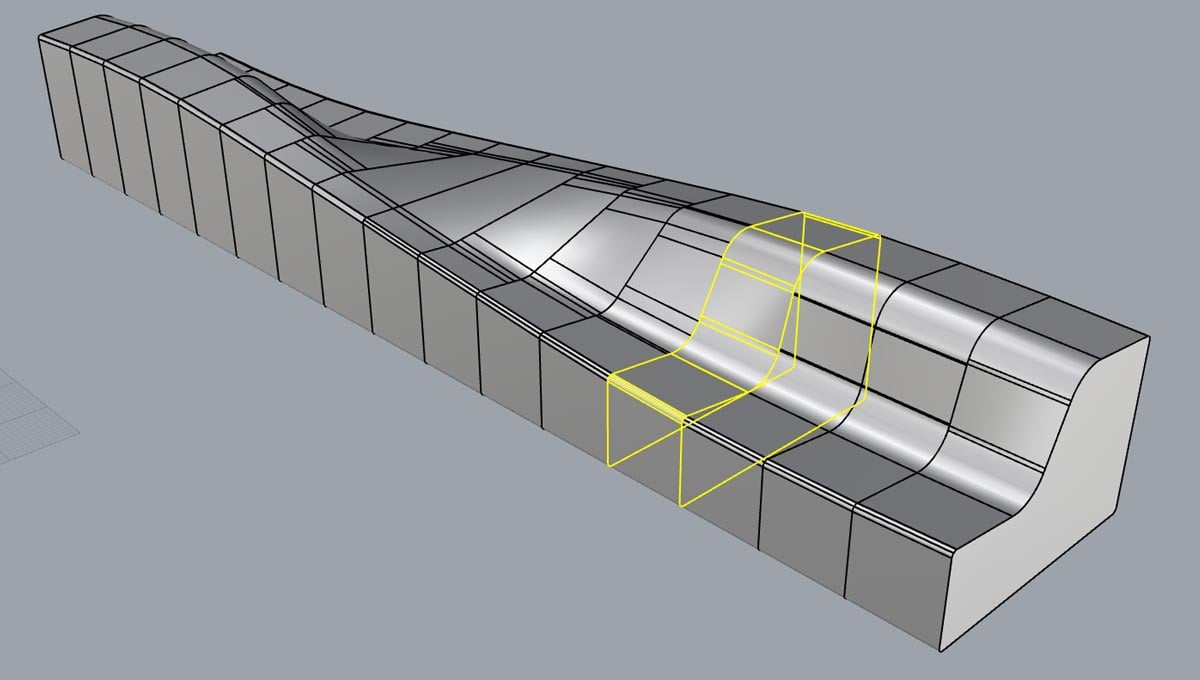

The bench pictured in the above schematic was machine fabricated in expanded polystyrene (EPS) on behalf of SOM as part of an exhibition display. Once a design is finalized, a CAM file can be produced to guide its production using different machines and materials.

Digital fabrication can take your next project to another level

Digital fabrication technologies elevate and amplify the human creativity and ingenuity responsible for some of the world’s greatest designs. Learn how the latest digital fabrication applications and tools can elevate your next project and accelerate its completion by scheduling a no-pressure introduction to Bridgewater Studio today. Our full-service design and fabrication company can show you how to leverage digital technology throughout your project from conception to completion. We’ll also customize a free project plan for you so you can start realizing your vision right away.

.png)

.png)

.png)