Looking to bring your wildest imaginations to life? Ready to revolutionize your business with cutting-edge prototypes? Then you've undoubtedly encountered the realm of additive manufacturing.

As leaders in custom fabrication, we understand that navigating through the ever-expanding array of 3D printing technologies can be as confusing as it is exciting. In this article, we’ll dive deep into two popular methods: FFF (or Fused Filament Fabrication) 3D Printing and Stereolithography (SLA).

So, whether you're an entrepreneur venturing into the world of rapid prototyping or an artist seeking to sculpt with light and plastic, we are here to guide you through the ins and outs of FFF and SLA 3D printing.

What is FFF 3D Printing?

Definition: Fused Filament Fabrication 3D printing, also known as Fused Deposition Modeling, or FDM, is a computer-aided digital fabrication technique that builds objects by depositing layers of material in a predetermined path, one layer at a time. With FFF, thermoplastic filament is pushed through a hot nozzle to liquify it, before it is selectively deposited in a pre-designed path, layer-by-layer.

Uses: FFF 3D Printing is a good choice for low-cost rapid prototyping. Because it utilizes lower-cost materials and the tool itself is inexpensive, it is more approachable for hobbyist fabricators. Additionally, it can be the tool of choice if more than one material needs to be printed to create the desired object.

Benefits: The biggest benefit of FFF is that it is the least expensive printer technology and uses the least expensive materials. Additional benefits include that FFF printers work with a large variety of materials including thermoplastics, wood, metal-infused thermoplastics, and even chocolate. It is easy to switch materials or build with more than one material, allowing creative applications. Plus, the printers and materials are widely available.

Challenges: FFF 3D printers lack the smooth finished surface and level of detail that SLA 3D printers offer. Additionally, they are not recommended for complex designs because of the potential for warping and material shifting. The level of detail is limited by the size of the nozzle and each layer is visible on the sides of the product. Overall quality can vary depending on the temperature of the bed and the extruder as well as printing speed. Additionally, all objects must be built up from a flat surface, restricting the types of designs that can be made.

What is SLA 3D Printing?

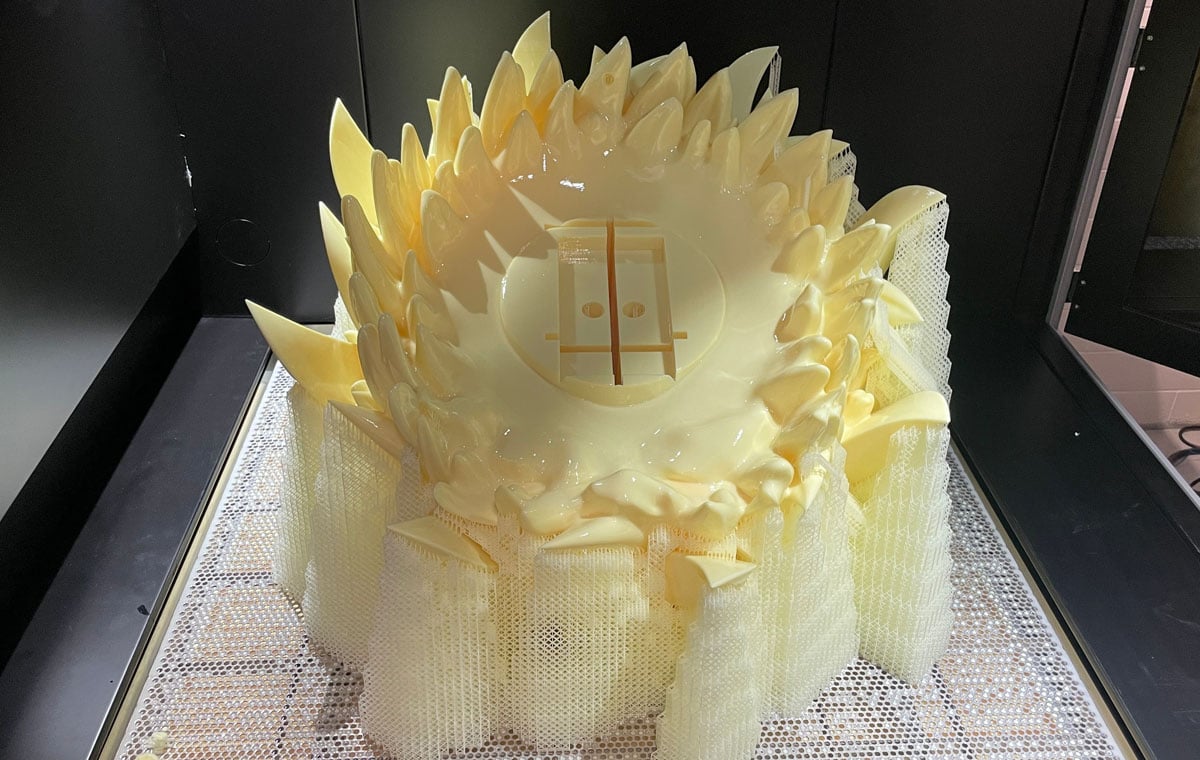

Definition: Stereolithography apparatus printers utilize liquid resin and UV lasers to turn a 3D model into an object by repeated exposure of a liquid photopolymer to a UV laser source.

Use: SLA 3D Printers are the best choice for highly detailed prototyping and component fabrication with smooth surfaces and high definition. They can be used to fabricate negative forms, molds, and multiple identical products. SLA Industrial printers are often used for machine parts, prosthetics, and decorative architectural elements, among many other applications.

Benefits: The mechanism of an SLA printer allows the printing of very thin layers (between 30-140 microns), resulting in fine detail and elaborate textures. SLA printers work quickly and with limited materials waste, and products can be built top-down or bottom-up, allowing greater versatility. The finished product is seamless and requires only minimal touch-ups..

Challenges: SLA printing technology is more expensive than FFF 3D printing – both in the cost of the materials and the printers themselves, but because the end result is so polished, it can provide cost savings over time since less hands-on finishing labor is required.

3D printing can be an invaluable tool for creating custom elements for commercial spaces, components or tools for modern industries, and even larger-than-life sculptures for themed entertainment venues. Choosing the right technology for your project is key to ensuring that the end result meets your objectives for durability and functionality whether you are looking for a simple and quick prototype or an elaborate architectural element.

At Bridgewater, we lean on Industrial SLA 3D printers to help us bring our client’s unique and engaging projects to life. Whether it's fabricating a photo pop-up booth or creating giant dragon sculptures for a themed restaurant, 3D printing is a powerful tool in our digital fabrication toolbox. Ready to leverage this exciting technology for your business or organization? Book a no-obligation introduction to Bridgewater Studio today and get a customized plan for your next project.

.png)

.png)

.png)